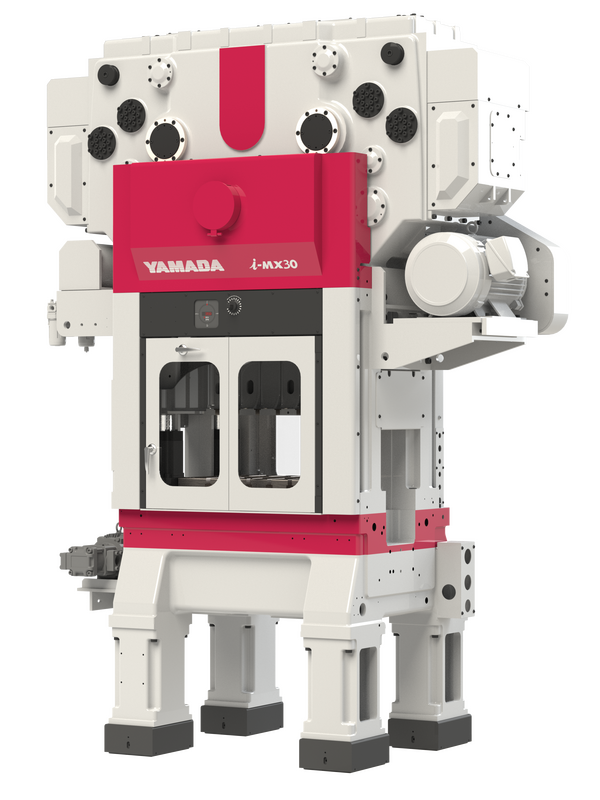

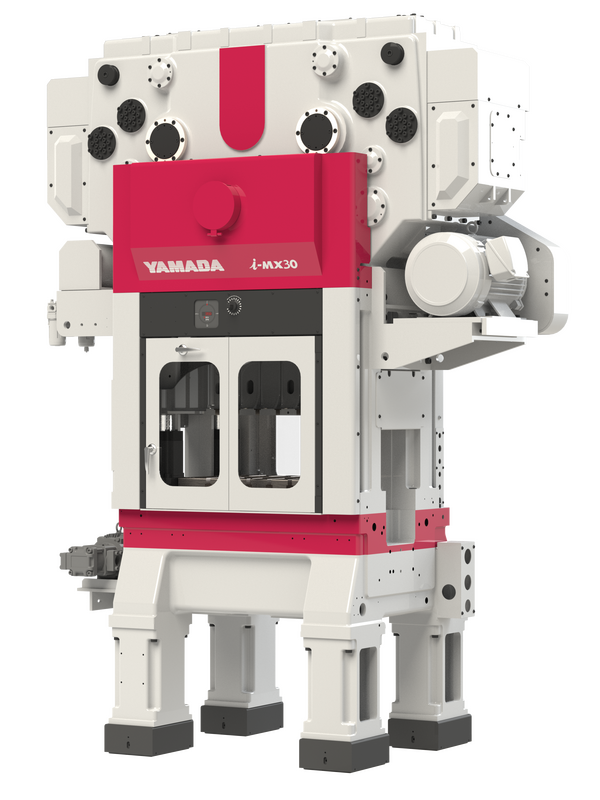

IMX Series

Link-Motion Press with Variable Stroke

and Advanced Motion Control.

With the innovative IMX-Series, YAMADA sets a new benchmark in high-speed, high-precision stamping. Equipped with our link-motion drive and advanced motion control, these presses deliver bottom-dead-center precision of ±2 µm at every speed and stroke, while rugged construction and real-time monitoring ensure unmatched performance, efficiency, and reliability for the most demanding stamping applications.

- Advanced Motion Control

- Automatic Stroke Height Adjustment

- Link-Motion Drive

- Wide Bolster Specifications

- Extended Industry 4.0 Features

/ Specifications

Technology That Powers

Precision and Performance

- Advanced Motion Control

- Automatic feedback system for unmatched precision at bottom dead center (BDC).

- Link-Motion Drive

- Reduced slide speed by ~30% near BDC for enhanced stability and accuracy.

- Extended Tool Life

- Optimized slide motion reduces wear, extending maintenance intervals.

- Reduced Vibrations

- Enhanced motion stability ensures consistent, high-quality results.

- 24" Touchscreen Control

- Intuitive, reliable interface for seamless operation.

- Automatic Stroke Adjustment

- Auto-saves and adjusts stroke height/parameters per tool on load.

- Quick Tool Change

- Stores parameters for up to 1000 tools for fast, flexible setups.

- Integrated Press-Force Monitoring

- Ensures process reliability and safety.

- Durable GGG-50 Press Body

- Robust construction for maximum stability.

- Dynamically Balanced Eccentric Shaft

- Machined to customer specification for precise, vibration-free operation.

- Guided Pressure Columns

- Six guides (2 pressure columns, 4 slide guides) for superior horizontal slide stability.

- Heat & Cool System

- Preheats machine for perfect parts from the first stroke.

/ IMX-Series

All models in the IMX series

- Cards

- Table

/ Facilities

Link-Motion Drive

Precision Where It Counts

The Link-Motion Drive is YAMADA’s innovative solution for achieving optimal slide motion in stamping presses. Unlike a conventional crank-motion drive, which moves the slide at a nearly constant speed throughout the stroke, the Link-Motion Drive intelligently reduces the slide speed by around 30 % in the critical stamping zone near bottom dead center (BDC).

This deceleration around the point of material forming ensures:

-

Improved Process Stability: The slide moves more smoothly through the active area of the tool, minimizing vibrations and deviations.

-

Higher Accuracy: Consistent bottom-dead-center positioning guarantees uniform part quality, even at high stroke rates.

-

Extended Tool Life: Reduced speed in the critical forming zone decreases wear, meaning tools need resharpening less frequently.

-

Optimized Production Efficiency: The slide moves faster outside the stamping zone where precision is less critical, balancing speed and quality.

In short, the Link-Motion Drive delivers unmatched precision, process stability, and less wear on your tools.

/ Facilities

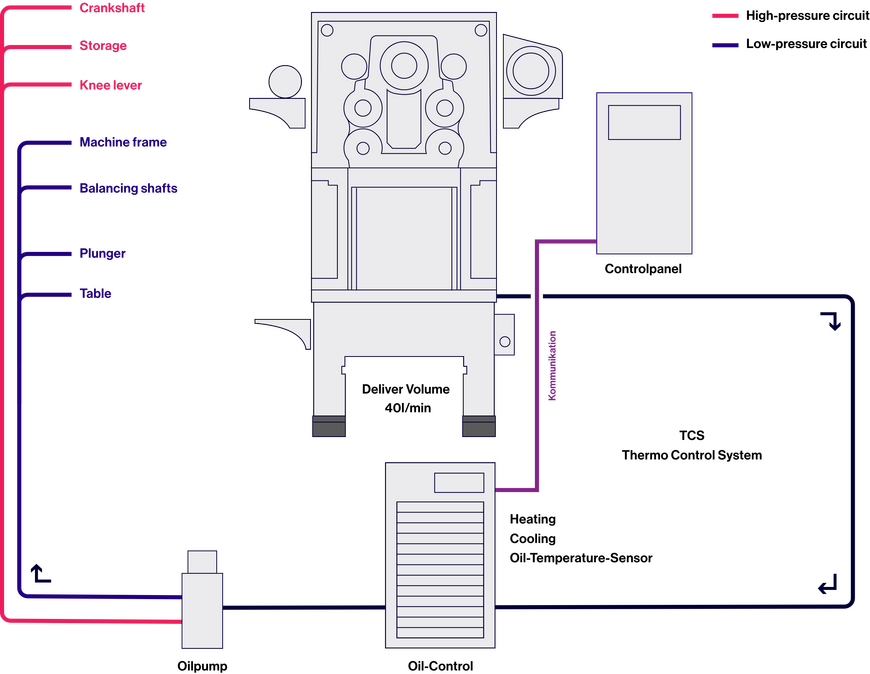

Heat & Cool System

Perfect Parts from the First Stroke

Precision starts at the very first stroke. Yamada’s Heat & Cool system keeps the press at a constant operating temperature — from the first part to the last. Before production begins, the system automatically heats the press frame and slide to the optimal temperature using a built-in timer, so the machine is ready when production starts — without any loss of time. Once running, a circulating oil loop maintains the temperature within ±1 °C through integrated heating and cooling.

The result: consistent part quality, stable accuracy, and less scrap — without any additional cost. The Heat & Cool system comes standard with every Yamada press, ensuring perfect performance right from the start.

- 24" Color Touchscreen Control

- YAMADA 24" touchscreen with 16 selectable languages, stores 1000 tool datasets (stroke height, stroke rate, tool installation height, feed parameters, tool designation, specific tool data).

- Heat & Cool System

- Automatic oil temperature regulation for consistent performance.

- Dynamic Slide Balancing

- Dynamically balanced slide for smooth, precise operation.

- Digital Angle & Stroke Rate Display

- Real-time monitoring of angle and stroke rate.

- Main Drive with Forward/Reverse

- Flexible operation with forward and reverse functionality.

- Digital Slide Height Display

- 0.001 mm accuracy with motorized adjustment and hydraulic clamping; includes Quick Stroke Lift (QSL) with auto-repositioning.

- YAMADA Active Control

- Automatic correction of slide penetration depth for precision.

- Dynamic Vibration Protection (D.V.P.)

- Vibration-damping machine feet for enhanced stability.

- Programmable Digital Outputs

- 10 programmable 24V outputs (cams) for customized control.

- Safety Inputs/Outputs

- Instant-stop and top-dead-center stop inputs, plus “clutch engaged” output for peripherals.

- YAMADA Press Force Monitoring

- Dual-channel system with piezo sensors on corner columns, displaying total and per-channel force, with tool protection via max/min force settings.

- Digital Counters & Meters

- 9-digit piece counter (up/down), ammeter, and operating hours counter.

- Digital Speed Display

- Real-time press speed monitoring.

- Oil & Air Pressure Monitoring

- Displays with automatic oversight for reliability.

- Two-Hand Operation Hardware

- Tactile buttons for two-hand operation (tip/micro-tip only with closed door), emergency stop, and top-dead-center stop.

- External Safety Signals

- 2 instant-stop and 2 top-dead-center stop inputs.

- Controlled Air Blow-Off

- Cam-operated blow-off with 4 cam outputs, plus constant air connection and blow-off gun.

- Lubrication Oil Channel

- Collection tray with 1.6L capacity for oil drainage.

- Safety Doors

- Front and rear safety doors for secure operation.

- Work Area Lighting

- Integrated illumination for enhanced visibility.

- Electrical Cabinet Cooling

- Cooling system for reliable electronics performance.

/ Service

Precision is more than just the product

Our high-speed presses play a critical role in producing the finest stamped metal components – from smartphones and connectors to highly efficient motor cores and bipolar plates. True quality extends beyond the machine itself, encompassing the comprehensive service, support, and expertise that ensure consistent performance and reliability for manufacturers worldwide.